Big jobs like building bridges, fixing ships, or making machines demand clean, tough surfaces. These surfaces must stay strong and smooth before painting or welding. Choosing the right cleaning method matters. More teams now turn to shot blasting because it works faster, digs deeper, and lasts longer.

Older cleaning methods—like scrubbing, soaking, or spraying—often miss spots, spill waste, and tire out workers. But a shot blasting machine, along with steel shot, can carve away rust and dirt, then shape the surface for its next job.

Let’s find out how shot blasting outshines older methods, and why teams like Itaichu (M) Sdn Bhd depend on it to get the job done right. This process not only saves time but also creates long-lasting results across many industries.

Understanding Shot Blasting

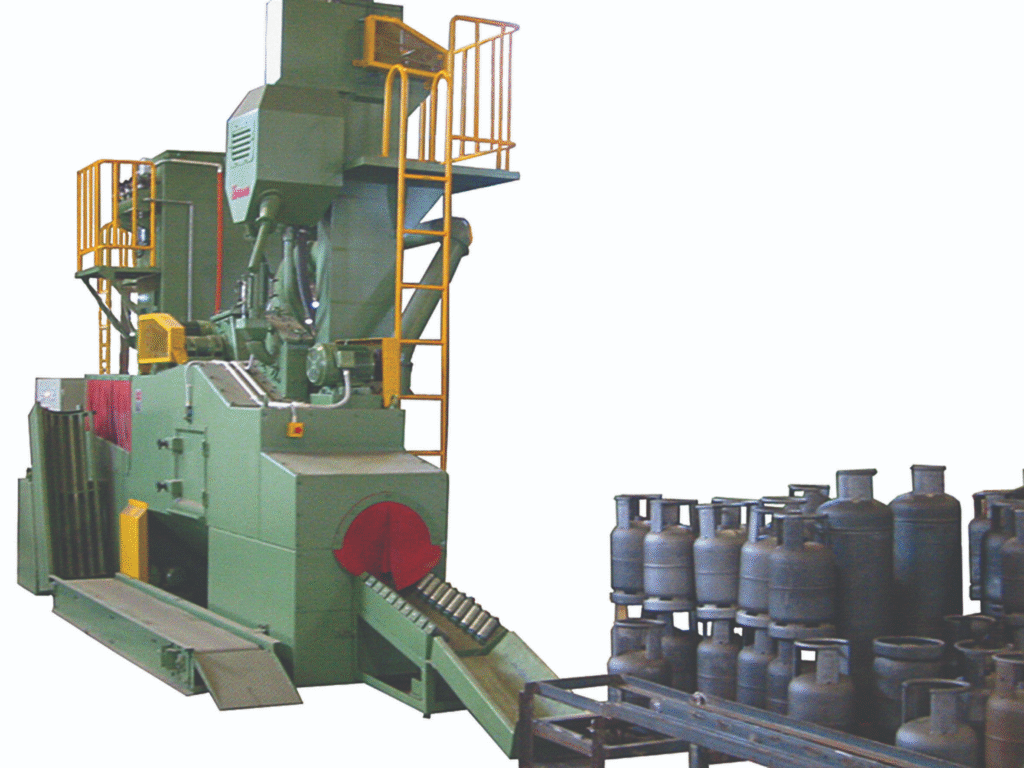

Shot blasting hurls steel shot at a surface with strong force. These round pellets chip off paint, rust, and grime. This process strips away old layers and reveals a fresh, solid finish.

The shot blasting machine uses a sealed chamber to control the direction, speed, and strength of each blast. It rattles through metal, stone, or concrete and never uses water or chemicals. It also prepares surfaces so that paint and coatings can stick well and stay longer.

This is ideal for teams operating in areas where water disposal is difficult or when maintaining dry surfaces is crucial for quality.

What Traditional Cleaning Methods Struggle With?

Old tools like brushes or sprayers still appear on small jobs, but they fall short in large tasks.

Brushing relies on hand power and takes too much time. Pressure washers drench surfaces and often leave behind water and slick spots. Chemicals may burn, smell, or spread badly. None of these tools reaches into tight spaces well.

They also weigh down workers and drag out project deadlines. For hard work or big surfaces, these methods just can’t keep up. Teams often need to redo the work or add extra hours, which increases both fatigue and frustration.

Key Advantages of Shot Blasting

1. Smooth and Strong Surface Finish

- Shot blasting blankets the whole surface evenly. It never skips spots or weakens on corners. That creates a base that paint, glue, or coating can cling to and hold tight.

- The shot blasting machine also cleans out deep cracks and edges. This gives a cleaner, stronger, and better-looking surface every time.

- By using this method, you ensure that paint won’t peel, flake, or bubble over time, which can lower future maintenance needs.

2. Quick Work for Big Spaces

- Shot blasting machines sweep over large areas quickly. A task that takes hours to scrub can be done in minutes with one trained worker and the right machine.

- That speed frees up workers for other jobs and pushes projects forward. Faster work also means fewer team members need to stay behind, saving energy and labour.

3. Fewer Costs Over Time

- Shot blasting slices away extra costs. It reduces waste, protects tools, and keeps surfaces solid longer. Coatings stick better and hold up stronger.

- Steel shot endures many blasts before it wears down. You don’t need to replace it often, unlike brushes or sand. Over time, this cuts supply costs and storage space as well.

Better Grip for Paint and Coatings

Paint needs a rough surface to latch on tightly. Smooth walls may look clean, but paint often slips off.

Shot blasting etches tiny grooves into the surface. That helps paint or glue dig in and stay longer. This holds up better against wind, rain, and wear.

In industries like shipyards or factories, a stronghold saves time and stops repeat work. It also reduces the chances of safety hazards caused by peeling surfaces.

Safer for Workers and Kinder to Nature

1. No Chemicals or Harsh Liquids

- Many old cleaners pour out strong chemicals that sting, smoke, and spill. These substances harm the air, soil, and even workers.

- Shot blasting skips all that. It uses dry steel shot, not wet sprays. That means no toxic mess and no leaks that seep into nature. It helps companies follow safety rules and meet environmental standards.

2. Cleaner Air at the Job Site

- Shot blasting machines trap dust inside filters. These systems catch fine particles and lock them away. This keeps workers breathing safely and the space clean.

- Safe air helps teams work longer, move faster, and stay focused. Better air also leads to fewer sick days and injury risks for the crew.

Useful in Many Jobs and Places

Shot blasting fits into many industries. It cuts through grime on steel, concrete, or stone. Whether you clean a bridge, factory floor, or ship, this method gets results.

Shot blasting helps:

- Builders

- Car and train makers

- Ship crews

- Oil workers

- Machine shops

The shot blasting machine also travels well. It works in open spaces or tight corners and adapts to any job. Mobile units make it even easier to blast in the field or at remote worksites.

Accurate and Easy to Control

Shot blasting machines let workers adjust blast speed, direction, and force. This gives precise, steady results without guesswork.

Machines come with switches, filters, and auto shut-off controls. This keeps the team safe and the process smooth. Even new workers can learn how to operate the equipment with basic training.

Accurate tools help workers nail the finish every time.

How Steel Shot Adds Power?

Steel shot does the hard work. These round bits slam into surfaces and break off tough layers without damaging the base.

Different sizes work for different jobs. Small shot smooths fine surfaces. Bigger ones punch through thick rust. The round shape slides across the metal instead of cutting into it.

Steel shot also outlasts other materials. It spins through many cycles before it needs changing. That makes it a top choice for companies that clean regularly.

Simple Care and Long Life

Shot blasting machines don’t break down easily. With basic care, they hold up for years. Workers can clear out dust, wipe down trays, and refill the shot in minutes.

Brands like Itaichu (M) Sdn Bhd craft machines built for long, heavy use. Their equipment handles stress and keeps going strong.

This saves money on repairs and replacements while keeping work moving without delay.

When Old Methods Still Work?

Sometimes, light jobs need soft touches. If you clean glass, plastic, or paint on a small sign, then a cloth or brush might work.

But if you face rust, thick paint, or wide surfaces, shot blasting will power through faster and better. It works best when time is short, and quality must stay high.

Compare Shot Blasting with Traditional Cleaning

Here’s how the two cleaning styles match up across key areas:

| Feature | Shot Blasting | Traditional Cleaning |

| Surface Finish | Even and textured | Uneven and patchy |

| Speed | Fast and strong | Slow and tiring |

| Waste Output | Dry and clean | Wet and messy |

| Worker Safety | Protected and filtered | Open to spills and fumes |

| Reuse Value | Steel shot lasts long | Tools wear out fast |

| Lifespan of Equipment | Sturdy and durable | Breaks and rusts quickly |

Choosing the Right Machine

Look for machines that:

- Let you change the shot speed and size

- Block dust and protect users

- Come with easy-to-clean parts

- Offer support from experts

A trusted provider like Itaichu (M) Sdn Bhd can guide you to the right machine for your job. They understand what tools match which tasks.

Conclusion

Shot blasting cuts deeper, cleans smarter, and lasts longer than old-school tools. It uses a strong shot blasting machine and steel shot to strip, shape, and ready surfaces for anything ahead.

If you clean metal floors, pipes, or beams, this method delivers faster work, cleaner air, and stronger results.

While old methods still help with small or gentle tasks, shot blasting leads the way in most big jobs.

Read More:-

What Are the Key Benefits of Using Automated Blasting Machines?

How to Select the Right Stainless Steel Shot for Your Blasting Application?

Why Brown Aluminum Oxide is the Secret to Superior Surface Preparation?