Ever wondered what transforms raw fabric into the vibrant, durable, and soft textiles we wear or use daily? Behind every colorful shalwar kameez or sturdy sofa cover lies a carefully chosen blend of chemicals for textiles working their magic to shape the fabrics we love. From dyeing vibrant hues to adding water-repellent finishes, these compounds are the foundation of Pakistan’s thriving textile industry, a global powerhouse. But are they safe for us, the environment, and the workers handling them? This blog unravels the most common chemicals used for textiles processing, their roles in creating textiles, and the safety measures ensuring they’re a friend, not a foe, to both people and the planet. Whether you’re a manufacturer sourcing from a chemical supplier or a consumer curious about your clothes, let’s stitch together the facts about textile chemicals and their safety!

What Are the Key Chemicals in Textile Processing?

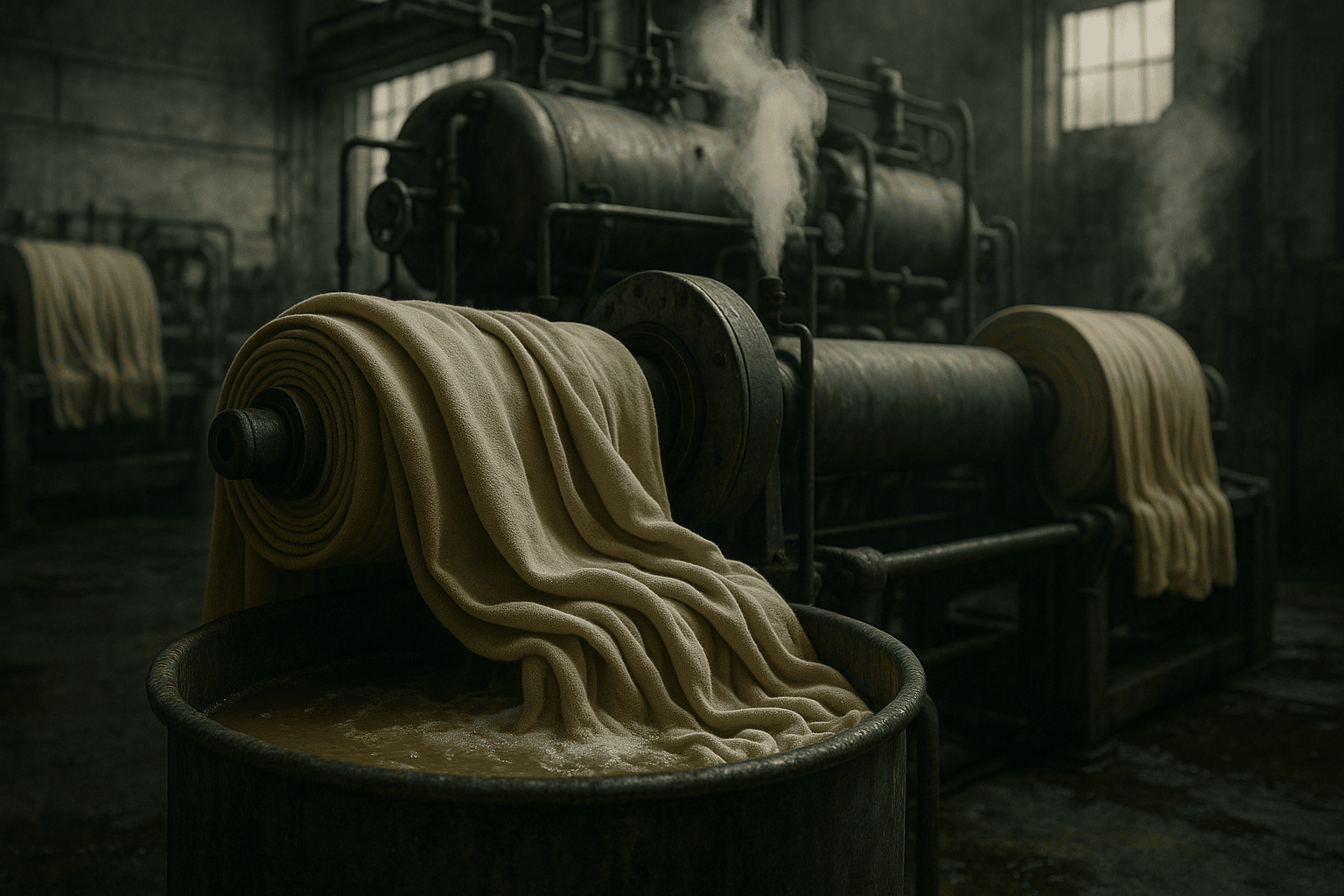

Textile production relies on a range of chemicals to transform raw fibers into finished fabrics with specific properties like color, texture, or durability.

- Surfactants: Non-ionic ethoxylated alcohols improve wetting and cleaning, ensuring dyes and finishes penetrate fabrics evenly.

- Dyes and Pigments: These add vibrant colors, bonding with fibers like cotton or polyester for lasting hues.

- Auxiliaries: Cellulose ethers enhance fabric thickness or water retention during processing, improving workability.

- Finishing Agents: Silicones or hydrophobic powders add softness, water resistance, or wrinkle-free properties to fabrics.

- Pakistan’s Role: As a textile hub, Pakistan relies on chemical suppliers in Pakistan to provide these compounds for local and export markets.

Chemicals weave the magic that turns plain threads into vibrant, lasting fabrics.

How Do Surfactants Improve Textile Processing?

Surfactants are critical for preparing fabrics by ensuring thorough cleaning and dye penetration.

- Wetting Power: Non-ionic surfactants, with cloud points around 63-80°C, allow water to spread evenly across fabrics, aiding dye absorption.

- Cleaning Efficiency: They remove impurities like oils or dirt from fibers, ensuring a clean base for further processing.

- Stability: With pH ranges of 5.0-7.0 and low water content (≤0.5%), surfactants maintain consistent performance in textile baths.

- Applications: Used in cotton, polyester, and blended fabrics, they’re vital for dyeing and finishing processes.

- Local Availability: Chemical suppliers in Pakistan offer bulk surfactants in 120-200 kg drums for large-scale textile production.

Why Are Dyes and Pigments Essential for Textiles?

Dyes and pigments breathe life into textiles, delivering the vibrant colors and visual appeal that define fashion and home decor in Pakistan and beyond. Reactive dyes chemically bond with fibers like cotton, ensuring colors stay vivid even after repeated washes, while pigments, such as those based on titanium dioxide, provide opacity and brightness for printed fabrics or coatings.

These chemicals are formulated to resist fading from Pakistan’s intense sunlight, making them ideal for outdoor textiles like awnings or vibrant traditional garments like shalwar kameez. Safety is a priority, with modern dyes designed to minimize skin irritation, meeting global standards for consumer use. The durability of these colors ensures fabrics maintain their aesthetic appeal over time, reducing replacement costs for consumers. Pakistan’s textile industry, a key player in global exports, depends on a steady supply of these chemicals to meet diverse market demands, from bold fashion statements to subtle home textile tones.

What Role Do Auxiliaries Play in Fabric Production?

Auxiliaries enhance the textile process by improving fabric handling and performance.

- Thickening Agents: Cellulose-based compounds, with viscosities from 400-200,000 mPa·s, add body to fabrics, aiding in smooth application.

- Water Retention: These agents keep moisture in fabrics during processing, ensuring even dye or finish distribution.

- Workability: They prevent sagging in thick pastes, ideal for printing or coating textiles.

- Versatility: Used in cotton, polyester, or blends, they support Pakistan’s diverse textile outputs.

- Eco Focus: Suppliers offer low-ash (≤5.0%) auxiliaries to reduce environmental impact during processing.

How Do Finishing Agents Boost Fabric Functionality?

Finishing agents give textiles their final touch, adding practical or aesthetic features.

- Softness: Silicon-based compounds create a smooth, soft feel, perfect for clothing or home textiles.

- Water Resistance: Hydrophobic agents, like silane-based powders, repel water, ideal for outdoor fabrics.

- Wrinkle Resistance: Chemical finishes ensure fabrics stay crisp, reducing ironing needs for busy consumers.

- Durability: These agents extend fabric life, resisting wear in high-use items like upholstery.

- Local Supply: Chemical suppliers in Pakistan provide finishing agents in bulk for large-scale textile mills.

Finishing agents are the final stitch, turning good fabrics into great ones.

Are Textile Chemicals Safe for Workers and Consumers?

Safety is a top concern, and modern textile chemicals are designed with strict standards to protect people.

- Worker Safety: Surfactants with mild irritant properties (e.g., eye or skin irritation) require proper handling, with suppliers providing safety guidelines.

- Consumer Safety: Dyes and finishes meet global standards, ensuring minimal skin contact risks in clothing or home textiles.

- Regulatory Compliance: Chemicals like amines or titanium dioxide pigments comply with international regulations like TSCA or DSL.

- Protective Measures: Manufacturers use gloves, masks, and ventilation to safeguard workers during chemical application.

- Pakistan’s Standards: Local suppliers ensure chemicals meet safety requirements for both domestic and export markets.

How Do Environmental Concerns Shape Textile Chemical Use?

The environmental impact of textile chemicals is a growing focus, with sustainable practices gaining traction.

- Water Usage: Dyeing processes use less water with modern chemicals, reducing wastewater in Pakistan’s textile hubs like Faisalabad.

- Eco-Friendly Options: Recycled or low-impact chemicals, like bio-based auxiliaries, cut pollution and energy use.

- Waste Management: Suppliers provide low-ash or low-moisture compounds to minimize environmental residue.

- Regulatory Push: Pakistan’s textile industry adheres to global eco-standards, driven by export demands.

- Green Innovation: Chemical suppliers in Pakistan offer sustainable alternatives to meet market and environmental needs.

What Makes Textile Chemicals Cost-Effective for Manufacturers?

Textile chemicals balance performance with affordability, supporting Pakistan’s competitive textile industry.

- Efficient Processing: Surfactants and auxiliaries speed up dyeing and finishing, cutting labor and energy costs.

- Bulk Availability: Suppliers offer chemicals in 120-200 kg drums or 1000 kg IBCs, reducing per-unit costs for mills.

- Durability Gains: Long-lasting finishes reduce fabric replacement, saving costs for consumers and manufacturers.

- Local Sourcing: Pakistan-based suppliers provide competitive pricing, minimizing import expenses.

- Custom Solutions: Tailored chemical formulations optimize usage, ensuring cost-effective production.

How to Choose a Reliable Chemical Supplier in Pakistan?

Selecting the right supplier ensures access to safe, effective chemicals for textiles.

- Quality Assurance: Look for suppliers offering tested chemicals with consistent purity, like ≥99.5% for certain compounds.

- Range of Products: Choose suppliers with diverse chemicals, from surfactants to finishing agents, for all textile needs.

- Timely Delivery: Reliable logistics to hubs like Karachi or Lahore prevent production delays.

- Technical Support: Suppliers should offer guidance on safe handling and application for optimal results.

- Sustainability Focus: Opt for suppliers with eco-friendly options to meet global textile standards.

What’s the Future of Textile Chemicals in Pakistan?

Textile chemicals are evolving to meet modern demands for performance and sustainability.

- Sustainable Innovations: Bio-based surfactants and low-impact dyes reduce environmental footprints.

- Smart Textiles: Chemicals are being developed for conductive or heat-resistant fabrics, used in wearable tech.

- Automation: Advanced chemical formulations support automated dyeing and finishing for faster production.

- Export Growth: Pakistan’s textile chemical demand grows with its $15 billion textile export market (2024 data).

- Local Expertise: Suppliers in Pakistan are adapting to global trends, offering innovative solutions for mills.

Textile chemicals are weaving a future where performance meets the planet’s needs.

Comparison Table of Textile Chemicals

| Chemical | Function | Key Properties | Applications | Packaging | Price (PKR/kg, 2025) |

| Non-Ionic Surfactant (TO3) | Wetting, cleaning | >99% purity, CAS 69011-36-5 | Dyeing, fabric cleaning | 120-200 kg drums | 500-700 |

| Non-Ionic Surfactant (TO5) | Wetting, washing | Cloud point 63-67°C, HLB 10.5 | Cotton, polyester dyeing | 120-1000 kg | 550-750 |

| Non-Ionic Surfactant (TO7) | Wetting, cleaning | Cloud point 72-76°C, HLB 12.2 | Fabric preparation | 120-1000 kg | 600-800 |

| Cellulose Ether | Thickener, water retention | Viscosity 400-200,000 mPa·s | Printing, coating | Various | 800-1,200 |

| Titanium Dioxide Pigment | Opacity, brightness | 95% TiO2, pH 7.0 | Textile coatings | Various | 1,000-1,400 |

FAQs About Textile Chemicals

What are the main chemicals used in textile processing?

Surfactants, dyes, auxiliaries, and finishing agents are key, aiding in wetting, coloring, and enhancing fabric properties.

Are textile chemicals safe for skin contact?

Modern chemicals meet global safety standards, minimizing irritation risks, though proper handling is needed during processing.

How do surfactants help in textile production?

They improve wetting and cleaning, ensuring even dye penetration and impurity removal for consistent fabric quality.

Can textile chemicals be eco-friendly?

Yes, bio-based surfactants and low-impact dyes reduce water use and pollution, offered by sustainable suppliers.

Why source chemicals from Pakistan suppliers?

Local suppliers provide cost-effective, high-purity chemicals with reliable delivery for Pakistan’s textile industry.

How do finishing agents improve textiles?

They add softness, water resistance, or wrinkle-free properties, enhancing fabric functionality and durability.

What’s the shelf life of textile chemicals?

Most, like surfactants or cellulose ethers, last 6-24 months when stored in cool, dry conditions.

How do chemicals affect textile costs?

They streamline processing and enhance durability, reducing production and replacement costs for manufacturers.

Are textile chemicals regulated in Pakistan?

Yes, they comply with local and global standards, ensuring safety for workers, consumers, and the environment.

Where can I find a chemical supplier in Pakistan?

Suppliers in Faisalabad, Karachi, or Lahore offer tested chemicals for textiles, with bulk and eco-friendly options.

Wrapping Up

Chemicals for textiles are the backbone of Pakistan’s vibrant textile industry, turning raw fibers into colorful, durable, and functional fabrics. From surfactants that ensure even dyeing to finishing agents that add softness or water resistance, these compounds drive quality and innovation. Safety and sustainability are key, with modern chemicals meeting strict standards to protect workers, consumers, and the environment. By choosing a reliable chemical supplier in Pakistan, manufacturers can access cost-effective, high-performance solutions tailored to their needs. Whether you’re crafting fashion for global markets or durable home textiles, these chemicals weave the foundation for success. Ready to power your textile production? Connect with a trusted supplier and create fabrics that shine with quality and care!