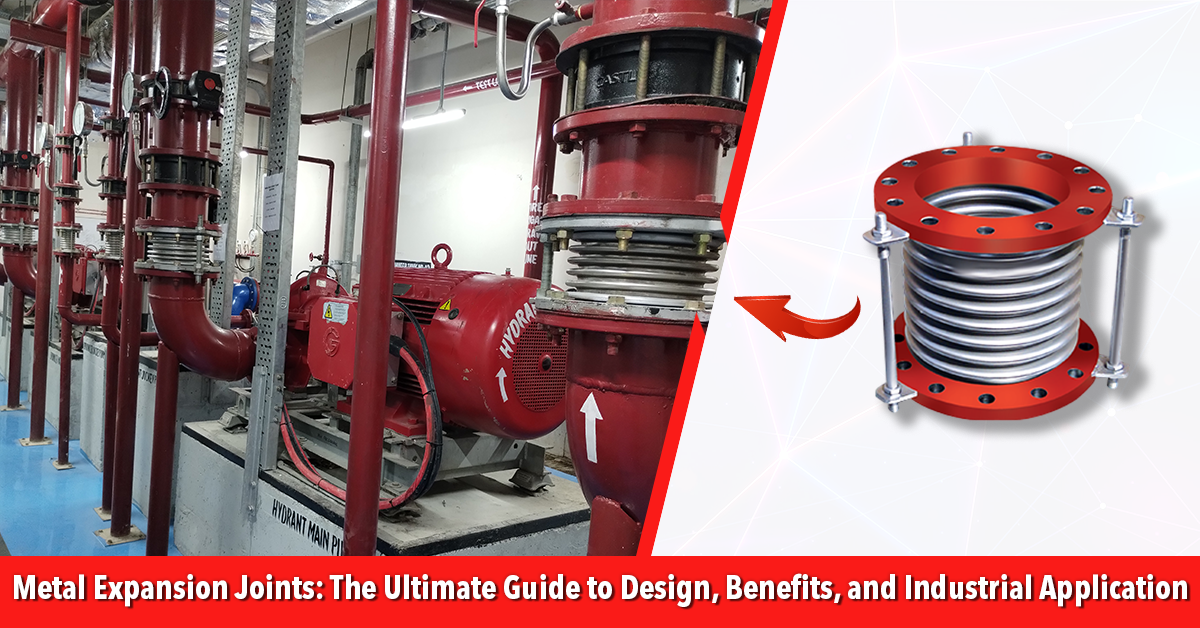

In industrial piping systems, managing thermal expansion, vibration, and misalignment is critical to ensure In industrial piping systems, managing thermal expansion, vibration, and misalignment is critical to ensure system longevity and performance. That’s where Metal Expansion Joints—also known as metallic bellows—come into play. These joints offer controlled flexibility and movement absorption, making them indispensable across a variety of industries.

At Resistoflex, we specialize in high-performance metallic expansion joints that deliver reliability even in the most demanding environments.

What Is a Metal Expansion Joint?

A metal expansion joint is a flexible component made of stainless steel or other alloys, designed to absorb dimensional changes in pipelines caused by:

- Thermal expansion and contraction

- Vibrations from pumps or motors

- Pressure variations

- Mechanical misalignments

The core of this component is the bellows, a corrugated metal tube that expands or contracts depending on the movement in the pipeline.

How Do They Work?

Metal expansion joints accommodate motion in multiple directions:

Type of MovementFunctionAxial MovementAllows the joint to expand or compress along its length due to temperature changes.Lateral MovementAbsorbs movement perpendicular to the axis, useful in case of misaligned pipe sections.Angular MovementAllows angular rotation for pipes that bend or are under dynamic stress.

These joints often come with tie rods, hinges, or gimbals to control or limit specific movements.

Key Benefits of Metallic Expansion Joints

1. High Temperature and Pressure Resistance

Metal bellows can withstand extreme temperatures (from -250°C to 1000°C) and high-pressure conditions, making them suitable for steam, exhaust, and chemical lines.

2. Durability and Corrosion Resistance

Made from stainless steel, Inconel, or other nickel alloys, metallic joints resist rust, chemical attack, and fatigue—ideal for long-term use in harsh environments.

3. Superior Vibration Absorption

When installed near rotating equipment such as pumps or blowers, metallic expansion joints significantly reduce vibration transmission. For added vibration control, consider our Spring Isolators designed for heavy-duty applications.

4. Compact Design

Compared to other types of expansion joints, metallic designs are compact, saving space and weight in high-density installations.

Common Applications Across Industries

Metal expansion joints are widely used across industries like:

- Power Generation (Steam lines, turbines)

- Oil & Gas (Refineries, pipelines)

- Chemical & Petrochemical

- Marine and Shipbuilding

- HVAC and Exhaust Systems

- Nuclear and Aerospace

These joints are often installed where high temperatures or pressure variations occur, ensuring structural integrity and reliability.

Comparison: Metal vs Rubber Expansion Joints

While Rubber Expansion Joints are also used for flexibility, they serve different purposes. Here’s a quick comparison:

FeatureMetal Expansion JointRubber Expansion JointTemperature RangeUp to 1000°CUp to 120°CPressure RatingVery HighModerateFlexibilityModerateHighVibration AbsorptionGoodExcellentChemical ResistanceHigh (with special alloys)Depends on rubber type

So, for high-temperature, high-pressure environments—metallic expansion joints are the clear winner.

Types of Metallic Expansion Joints at Resistoflex

We offer a wide range of configurations depending on your application:

- Axial Expansion Joints – For straight pipelines with thermal movement.

- Universal Expansion Joints – Handles axial and lateral movement using two bellows and a center pipe.

- Hinged Expansion Joints – Controls angular motion using hinge mechanisms.

- Gimbal Expansion Joints – Allows angular movement in multiple planes.

- Pressure Balanced Joints – Maintains constant pressure load on piping anchors.

Each of these types is custom-engineered at Resistoflex Heavy Industry Solutions to match client-specific operational needs.

Installation & Maintenance Tips

- Correct Alignment: Ensure pipes are properly aligned before installation to avoid overloading the bellows.

- Support and Anchoring: Use fixed anchors and guides to direct motion to the joint.

- Regular Inspections: Check for signs of fatigue, corrosion, or leakage.

- Avoid Torsional Load: Never twist the expansion joint during installation.

Pro tip: combine metallic joints with vibration isolation systems for optimal performance.

Why Choose Resistoflex for Metal Expansion Joints?

- ✔️ Over 50+ years of engineering excellence

- ✔️ Custom designs for critical applications

- ✔️ In-house testing and quality control

- ✔️ Wide material selection – SS304, SS316, Inconel, etc.

- ✔️ Trusted by defense, power, and chemical sectors

We’re more than just a manufacturer—we’re a solution partner for industries where failure is not an option.

Conclusion

In the world of industrial piping, Metal Expansion Joints are not just components—they’re protectors of infrastructure. They absorb thermal expansion, reduce vibration, and improve overall system longevity.

If your system demands performance under pressure—literally—choose metallic expansion joints from Resistoflex. For more details or customized solutions: