Selecting the correct studs and tracks is one of the most important steps in ensuring a safe, durable, and cost-effective building. Whether you’re working on a commercial, residential, or industrial property, the quality and specifications of the framing materials will directly impact structural integrity, design flexibility, and compliance with building codes. With steel framing increasingly replacing timber in many projects, understanding how to choose the right steel studs and tracks—including non-load bearing studs and tracks—is crucial for any architect, engineer, or contractor involved in modern steel framing solutions.

1. Understanding Steel Framing Solutions

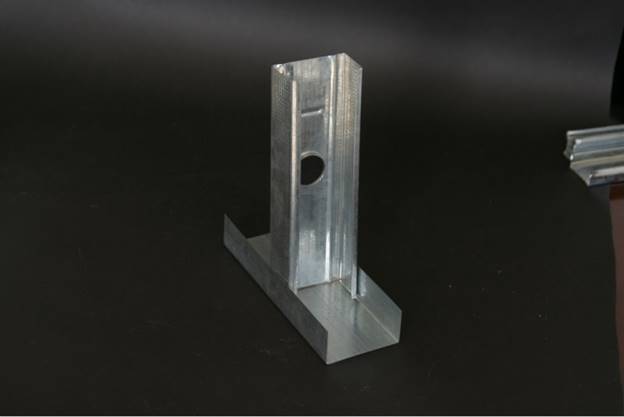

Steel framing solutions provide an alternative to traditional wood framing, offering strength, durability, and design versatility. Steel framing uses cold-formed steel components, primarily studs and tracks, to create walls, partitions, and ceilings.

- Steel studs form the vertical members in a wall, much like wood studs.

- Steel tracks act as horizontal channels at the top and bottom, holding the studs in place.

This system is widely used for interior walls, exterior walls, and ceiling assemblies because of its fire resistance, uniformity, and ability to support heavy loads without warping or shrinking.

When selecting materials for your project, you need to distinguish between load-bearing studs and tracks and non-load bearing studs and tracks. Each has its own structural and cost implications.

2. Load-Bearing vs. Non-Load Bearing Studs and Tracks

The first step is to determine whether your walls are load-bearing or non-load bearing:

- Load-bearing studs and tracks are designed to support structural loads from floors, roofs, or other building components above them. They are typically heavier gauge steel with greater depth and thicker coatings to withstand higher stresses.

- Non-load bearing studs and tracks are used for interior partitions or walls that do not carry structural loads. They are lighter, easier to handle, and more economical than load-bearing options.

Misidentifying the type of wall can lead to under-specifying the framing components, which compromises safety and code compliance. Always consult your project’s structural drawings and local building codes before purchasing materials.

3. Key Factors to Consider When Selecting Studs and Tracks

a. Gauge (Thickness) of Steel

Steel studs and tracks come in various gauges, commonly ranging from 25 gauge (lightest) to 12 gauge (heaviest).

- For non-load bearing studs and tracks, gauges from 25 to 20 are typical for interior partitions.

- For load-bearing steel framing solutions, heavier gauges from 20 to 12 may be required depending on the load.

Thicker steel increases strength but also adds weight and cost. Selecting the appropriate gauge requires balancing structural needs with budget.

b. Width and Depth

Studs are produced in standard widths—1-5/8”, 2-1/2”, 3-5/8”, 4”, 6”, and 8” are common. Wider studs provide greater lateral stability and allow for more insulation or mechanical systems within the wall cavity. Match the stud width with your design requirements, especially for taller walls or those requiring extra acoustic or thermal insulation.

c. Corrosion Protection

All steel studs and tracks should be coated to resist corrosion. The most common is zinc galvanization, measured in ounces per square foot (G40, G60, or G90). In high-humidity areas, coastal environments, or buildings with stringent fire codes, you may need a heavier coating or even stainless steel to ensure long-term performance.

d. Fire and Acoustic Performance

Steel framing is inherently non-combustible, which makes it attractive for fire-rated assemblies. However, selecting the correct gauge, width, and spacing of studs and tracks also affects fire and sound ratings. For projects where acoustic performance matters (such as hospitals, schools, or multifamily units), opt for wider studs with resilient channels and additional insulation to meet STC (Sound Transmission Class) requirements.

e. Length and Customization

Studs come in standard lengths, but manufacturers often offer custom lengths to reduce cutting waste on-site. For large commercial projects, ordering pre-cut steel studs and tracks to exact specifications can significantly save labor time and reduce scrap material costs.

4. Compliance with Codes and Standards

Modern construction requires adherence to local building codes and industry standards. In North America, cold-formed steel framing components typically comply with ASTM standards such as ASTM C645 for non-load bearing studs and tracks and ASTM C955 for load-bearing studs.

Before selecting a supplier, confirm that their products are certified and tested according to these standards. Compliance not only ensures safety but also simplifies inspections and insurance approvals.

5. Sourcing Quality Steel Studs and Tracks

Choosing a reputable manufacturer or supplier is just as important as selecting the right specifications. Look for suppliers who:

- Provide mill certificates or product data sheets.

- Offer consistent dimensions and galvanization coatings.

- Can deliver large orders on time to prevent project delays.

- Have technical support staff to help with load calculations and design optimization.

Working with a reliable partner reduces the risk of receiving substandard materials and helps maintain construction schedules.

6. Installation Considerations

Even the best steel studs and tracks won’t perform as intended if installed incorrectly. Here are a few best practices:

- Ensure tracks are securely fastened to floors and ceilings before inserting studs.

- Use the correct screws or fasteners recommended by the manufacturer.

- Maintain consistent spacing (usually 16” or 24” on center) to match drywall or sheathing requirements.

- For tall walls or high-load areas, consider using bridging or bracing to prevent stud twisting.

Following these practices ensures that your steel framing solutions achieve their intended strength, fire rating, and acoustic performance.

7. Cost vs. Performance

While cost is always a concern, opting for the cheapest studs and tracks can lead to higher expenses later in the form of repairs, code violations, or poor performance. Consider the total life-cycle cost of your framing materials, including labor, maintenance, and energy efficiency.

8. Sustainability Benefits

Steel framing is inherently recyclable. Choosing high-quality steel studs and tracks contributes to sustainability certifications such as LEED. Some suppliers offer recycled-content documentation, which can help your project earn green building credits.

9. Common Mistakes to Avoid

- Using non-load bearing studs and tracks in load-bearing walls. This is one of the most critical errors and can lead to catastrophic structural failure.

- Ignoring local codes. Different regions may have unique requirements for gauge, coating, or spacing.

- Mixing products from different manufacturers. Slight variations in dimensions can complicate installation.

Avoiding these mistakes will save time, money, and potential liability.

10. Final Checklist for Selecting the Right Steel Studs and Tracks

- Identify wall type – load-bearing or non-load bearing studs and tracks.

- Determine gauge and width – match to structural and design requirements.

- Check coatings – ensure proper corrosion protection for your environment.

- Review fire and acoustic needs – select stud spacing and width accordingly.

- Verify code compliance – look for ASTM or equivalent certifications.

- Choose a reputable supplier – with consistent quality and on-time delivery.

- Plan installation – order correct lengths and consider pre-cut options.

Following this checklist ensures that your steel framing solutions deliver on safety, performance, and cost-effectiveness.

Conclusion

The success of any building project depends heavily on the quality and suitability of its framing system. By carefully considering gauge, width, coating, code compliance, and supplier reliability, you can select the right steel studs and tracks for your needs. Distinguishing between load-bearing and non-load bearing studs and tracks is essential to meet structural requirements and maintain safety standards.

With the right planning and supplier partnerships, modern steel framing solutions can provide you with stronger walls, faster installation, and long-term durability—helping your project meet both today’s demands and tomorrow’s challenges.