Ever grabbed a sugar stick at a café, popped open a travel-sized face cream, or tossed a protein powder sachet into your gym bag? Those handy little packets didn’t just appear out of nowhere—they’re the work of stick pack packaging machines, the quiet champs of modern packaging. These clever machines churn out slim, single-serve pouches that make life easier for consumers and keep production lines humming for businesses. In industries like food, pharmaceuticals, and cosmetics, where precision and convenience are everything, these machines are like a trusty sidekick, packing products with speed and care. Let’s take a closer look at how these industries lean on this automatic packaging machine to deliver your favorite products in perfectly portioned packs.

Stick pack machines are like baristas for packaging—whipping up single-serve pouches with the precision of a perfect latte pour.

What Are Stick Pack Machines All About?

A stick pack Packaging machine is a specialized piece of equipment that forms, fills, and seals narrow, tube-shaped pouches—think of those slim packets you tear open for ketchup or vitamin powder. They’re built to handle small, precise doses, making them a favorite for industries that need compact, consumer-friendly packaging. From shaping film into pouches to sealing them tight. These machines do it all in one go, saving time and keeping things consistent. They’re like the multitasking hero of the factory floor, perfect for businesses big and small.

How Do These Machines Work Their Magic?

Stick pack machines are like a well-oiled assembly line in a box. Here’s the step-by-step breakdown:

- Film Feeding: A roll of flexible film is loaded and pulled through. Kept straight and smooth to avoid any hiccups that could mess up the pouch shape or waste material.

- Pouch Shaping: The film is molded into a skinny tube using rollers and guides. Creating the stick pack’s signature slim profile, ready to hold anything from sugar to serums.

- Product Filling: A filler drops in just the right amount of product—powders, liquids, or gels. Ensuring every pouch is perfectly portioned for single-use convenience.

- Sealing: Heat or ultrasonic sealing locks the pouch tight, keeping contents fresh and safe from air or moisture. So your product stays good until it’s opened.

- Cutting and Delivery: The machine slices the pouches into individual sticks and spits them out. Ready for boxing or shipping, often at lightning-fast speeds.

Touchscreen controls make it easy to tweak settings, so you’re always in charge of the process.

Why Do Food Businesses Love Stick Pack Machines?

The food industry thrives on convenience, and stick packs deliver:

- Single-Serve Snacks: Instant coffee, sugar, or spice mixes are packed for quick use. Perfect for cafés or home kitchens where customers want grab-and-go options.

- Portion Control: Pre-measured doses make it easy for consumers to use just what they need. Reducing waste and keeping meals or drinks consistent.

- Freshness Guaranteed: Airtight seals lock in flavor for sensitive items like ground spices or drink powders. Ensuring every packet tastes as good as the first.

- On-the-Go Appeal: Slim pouches slip into pockets or lunchboxes. Catering to busy folks who need quick snacks or seasonings without the bulk.

How Do Pharma Companies Use Stick Packs?

Precision is critical in pharmaceuticals, and stick pack machines shine here:

- Accurate Dosing: They measure exact amounts of powdered or liquid medicines, ensuring patients get the right dose every time, which is crucial for safety and efficacy.

- Sterile Packaging: Stainless steel designs meet strict hygiene standards, preventing contamination and keeping medications safe for use in hospitals or homes.

- Portable Solutions: Single-use packets are easy for patients to carry, whether for travel or daily meds, making adherence to prescriptions a breeze.

- Tamper-Proof Seals: Secure closures give patients confidence that their medication hasn’t been compromised, building trust in the product and brand.

In pharma, stick pack machines are like a pharmacist you can always count on—delivering precise doses in packets that fit right in your pocket.

What’s the Role of Stick Packs in Cosmetics?

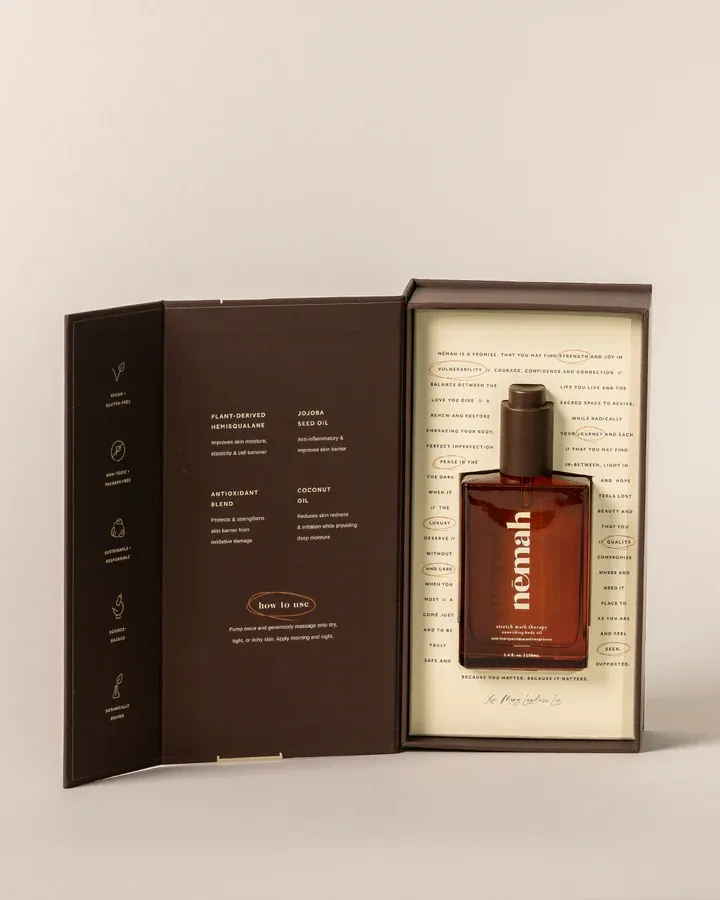

Cosmetics brands use stick packs to make their products pop:

- Travel-Friendly Packaging: Single-use serums, lotions, or face masks fit perfectly in purses or carry-ons, ideal for jet-setters or trial-size promotions.

- Precise Application: Pre-measured doses ensure customers use just the right amount, avoiding overuse and keeping skincare routines consistent.

- Shelf Appeal: Custom-printed pouches with vibrant designs grab attention in stores, helping brands stand out in a crowded beauty market.

- Freshness Protection: Airtight seals keep sensitive formulas like anti-aging creams fresh, so customers get the full benefits with every use.

How Do Stick Pack Machines Keep Production Smooth?

These machines are built to keep your factory running like a dream:

- Fast Output: Multi-lane models can produce up to 800 stick packs per minute, perfect for keeping up with high demand during peak seasons or product launches.

- Automation: They handle everything from forming to sealing, cutting down on manual labor and letting your team focus on other tasks like marketing or recipe tweaks.

- Low Waste: Precise dosing and sealing mean less product and film go to waste, saving you money and keeping your production line lean.

- Easy Adjustments: Quick changeovers let you switch between products or pouch sizes without long pauses, so you’re always ready for the next order.

Can Stick Pack Machines Handle Messy Products?

Sticky gels or fine powders? No problem:

- Custom Fillers: Piston fillers tackle liquids like honey, while auger fillers handle powders like protein supplements, ensuring clean, accurate fills every time.

- Clean Design: Stainless steel surfaces are easy to wash down, keeping things hygienic and preventing cross-contamination between batches of different products.

- Sealing Strength: Airtight seals prevent leaks, so even messy liquids like sauces stay contained, keeping your production line spotless and efficient.

- No-Spill Features: Sensors ensure pouches are filled only when properly formed, reducing spills that could slow down your operation or waste product.

What Features Make Stick Pack Machines a Smart Choice?

Choosing the right machine means looking at what it can do:

- Lane Flexibility: Single-lane for small runs or up to 16 lanes for big production, letting you scale up as your business grows without needing a whole new setup.

- Film Options: Works with various films, including eco-friendly ones, so you can cater to environmentally conscious customers while keeping costs manageable.

- User-Friendly Controls: Touchscreen PLCs make setup and tweaks a breeze, even for operators who aren’t tech wizards, keeping your line running smoothly.

- Durable Build: Made with tough materials like stainless steel, these machines handle long shifts and tough conditions, giving you years of reliable service.

How Do Stick Packs Boost Your Brand’s Image?

Packaging is your brand’s first hello to customers, and stick packs make it memorable:

- Eye-Catching Designs: Printed film lets you show off bold logos or colors, making your pouches stand out on shelves or in vending machines.

- Consumer Convenience: Slim, portable pouches appeal to busy customers, whether they’re grabbing a coffee stick or a skincare sample on the go.

- Customizable Sizes: Adjust pouch lengths or seal styles to match your brand’s vibe, creating a cohesive look that customers recognize and trust.

- Eco-Friendly Options: Use recyclable films to appeal to green-minded shoppers, showing your brand cares about the planet as much as they do.

How Easy Is It to Keep These Machines Running?

Maintenance is a breeze, so your production stays on track:

- Simple Cleaning: Stainless steel surfaces wipe down quickly, keeping things hygienic for food or pharma and getting you back to packing in no time.

- Routine Checks: Regular inspections of fillers and seals catch small issues before they turn into big delays, saving you time and repair costs.

- Easy Repairs: Non-proprietary parts mean you can fix things fast and affordably, without waiting weeks for specialized components to arrive.

- Software Updates: Keep the control system current with regular updates, ensuring your machine stays compatible with new tech and runs smoothly.

Stick pack machines are like a reliable friend—always there, easy to work with, and ready to make your products shine.

Comparison Table of Stick Pack Machines

Here’s a comparison of three stick pack machines to help you find the right fit:

| Feature | Single-Lane Stick Pack | Multilane Stick Pack – Medium | Multilane Stick Pack – High Output |

| Output | 40 stick packs/min | 300 stick packs/min | 800 stick packs/min |

| Lanes | 1 lane for small batches | 6 lanes for medium runs | 16 lanes for high-volume production |

| Max Pouch Width | 1.5 inches for compact packets | 1.5 inches for versatile sizing | 1.5 inches for consistent stick packs |

| Max Pouch Length | 7.5 inches for standard pouches | 8 inches for slightly longer packs | 8 inches for high-output efficiency |

| Material | #304 Stainless Steel for durability | #304 Stainless Steel for rugged use | #304 Stainless Steel for long-term reliability |

| Filler Type | Volumetric or piston for simple fills | Piston or auger for varied products | Multi-head or piston for fast, precise filling |

| Applications | Sugar, small-batch cosmetics | Drink mixes, medium-scale pharma | Large-scale pharmaceuticals, food powders |

| Best For | Startups with limited space | Growing businesses with steady demand | Large manufacturers with high output needs |

| Control System | Touchscreen PLC for easy operation | Touchscreen PLC for reliable control | Advanced PLC with diagnostics for efficiency |

| Footprint | Compact for small factories | Moderate for mid-sized lines | Larger but optimized for high throughput |

FAQs About Stick Pack Machines

What are stick pack machines used for?

They create slim, single-serve pouches for products like coffee, medicines, or creams, offering fast, precise packaging for multiple industries.

How fast can stick pack machines run?

Speeds range from 40 stick packs per minute for single-lane models to 800 for multi-lane systems, handling both small and large runs.

Can stick pack machines pack liquids?

Yes, piston fillers ensure accurate, leak-proof packaging for liquids like gels or sauces, keeping products safe and mess-free.

Are stick pack machines good for small businesses?

Single-lane models are compact and budget-friendly, perfect for startups packing small batches of snacks or cosmetics.

Do stick pack machines meet hygiene standards?

Stainless steel designs with washdown features comply with food and pharma safety rules, ensuring clean, contamination-free packaging.

What maintenance do stick pack machines need?

Regular cleaning, inspections, lubrication, and software updates keep them running, with non-proprietary parts for quick fixes.

Can stick pack machines create branded pouches?

Yes, they support printed film and custom seal styles, creating eye-catching pouches that boost your brand’s shelf appeal.

Which stick pack machine is best for high-volume production?

Multi-lane models with up to 800 stick packs per minute are ideal for large-scale operations like pharma or food manufacturing.

Can stick pack machines handle sensitive products?

Custom fillers and airtight seals protect delicate items like powders or serums, ensuring quality and safety.

How do stick pack machines save costs?

Automation cuts labor, precise dosing reduces waste, and durable designs minimize repair costs, keeping your budget in check.

Wrapping It Up

Stick pack machines are like the friendly, hardworking teammate every food, pharma, or cosmetics business needs. They churn out slim, single-serve pouches with speed and precision, making life easier for consumers and keeping your production line smooth. Whether you’re packing instant coffee for a café, medicines for a pharmacy, or serums for a beauty brand, these machines deliver consistent, professional results. With options from compact single-lane models for startups to high-output multi-lane systems for big players, there’s a stick pack machine ready to help your business thrive. Add some custom-printed film, and you’ve got packaging that not only protects your product but also makes it the star of the shelf.