High-Performance HDPE Geomembrane for Industrial Applications

Overview

HDPE geomembranes have become vital accoutrements in moment’s artificial world, where structural integrity and environmental safety are of utmost significance. These sheets of high- viscosity polyethylene are strong walls that regulate fluid movement in a variety of settings, similar as water budgets, mines, and tips. They’re a favored option for masterminds and contractors seeking both compliance and performance because of their remarkable chemical resistance and long- term continuity. In order to satisfy the requirements of snappily changing requests, HDPE Geomembrane manufacturers in India are adding inventions as companies strive for further reliable and affordable results.

The Benefits of HDPE Geomembrane for Industrial Applications

The way that companies handle Sheet operation, water conservation, and constraint systems has been greatly impacted by the growing environmental restrictions and growing mindfulness of sustainable practices. HDPE Geomembrane liners are now the recommended option as a result of this change. A great option for long- term operation, these liners are famed for their remarkable resistance to chemicals, UV shafts, and severe rainfall.

Due in part to the product’s adaptability to severe stress, HDPE Geomembrane liner manufacturers continue to witness an increase in demand. HDPE liners give constraint without immolating safety in a variety of settings, including artificial effluent treatment shops, external tips, and monoculture ponds. They can acclimatize to settling and altering ground conditions, which are typical in numerous artificial installations, because of their strength and inflexibility.

Uses in factual Artificial surroundings

HDPE geomembranes are essential for constructing impermeable walls in artificial settings. For example, leachate control is a crucial problem in mining operations. These processes frequently produce toxic and acidic derivations, which, if inaptly controlled, may contaminate groundwater. In these situations, HDPE liners are extensively employed to cover the bottom of chase ponds and leach pads, offering a robust hedge against environmental troubles.

Analogous to this, long- lasting filling results are demanded for Sheet recesses and ash dykes in the power generating assiduity, especially in thermal shops. In addition to reducing the possibility of soil impurity, the use of HDPE geomembranes guarantees nonsupervisory compliance. Accoutrements that can repel hydrocarbon penetration are necessary in the oil painting and gas sector for the safe storehouse of energies and the constraint of petrochemical Sheets. HDPE liners effectively fulfill this function because of their non-reactive nature.

HDPE Geomembranes are used in water saving enterprises in addition to constraints. These liners are used to line budgets, tanks, and conduits to stop seepage and water loss in areas where water deficit is an issue. further affordable and durable kinds are being produced by HDPE Geomembrane manufacturers in India as they continue to introduce, broadening the variety of uses.

The Value of opting the Correct Manufacturer

Not every geomembrane is made inversely. The manufacturer’s manufacturing norms and material procurement have a significant impact on the HDPE liner’s quality and continuance. In order to fulfill both original and transnational conditions, estimable manufacturers of HDPE Geomembrane Liners make sure that their products go through expansive quality testing. Every element of the geomembrane is examined to ensure peak performance, from tensile strength to resistance to environmental stress cracking.

Also, manufacturers are more suitable to give liners that are customized to meet particular artificial requirements when they engage in slice- edge extrusion technology and ongoing exploration and development. When creating constraint systems for high- threat or sensitive areas, this becomes essential. As India becomes a center for artificial- grade geomembranes, both original and transnational consumers are decreasingly looking to Indian businesses for nicely priced, superior products.

Comprehending HDPE Geomembrane Cost rudiments

The HDPE Geomembrane Price is a constantly asked question by purchasers and design itineraries. The consistency of the liner, face treatment( textured or smooth), quality instruments, and order volume are some of the variables that might affect the price. Crucially, indeed when fiscal limitations are reasonable, immolating quality may eventually affect large losses, particularly for important structure systems.

The quality of HDPE geomembrane is maintained at reasonable prices by estimable Indian manufacturers. Working with manufacturers that give specialized backing, point-specific advice, andpost-installation help is always advised. continuity, simplicity of installation, and conservation requirements should all be included in the total cost of power.

Environmental Impact and Sustainability

Given that HDPE geomembranes are fully recyclable and have a lower carbon footmark than numerous conventional constraint accoutrements , they give a fresh benefit in light of growing sustainability enterprises. They’re an ecologically friendly option as their operation greatly lowers the chance of polluting soil and groundwater.

Likewise, eco-certifications or green compliance are now needed for numerous large- scale systems, and HDPE liners frequently meet these conditions because of their low environmental effect during both manufacture and operation. This green edge is further enhanced by manufacturers that maintain sustainable practices in their operations.

Innovation and Upcoming Patterns

HDPE Geomembrane systems’ future depends on ongoing invention. New phrasings are being created to ameliorate resistance against UV declination, chemical assault, and advanced temperatures as a result of developments in polymer wisdom. Multilayered geomembranes, which combine the advantages of HDPE with other accoutrements to give advanced performance, are also gaining fashionability.

Also popular are smart liners with erected- in detectors for real- time leak monitoring, particularly in precious structure systems. In addition to adding safety, these technological advancements will lessen the need for reactive conservation and physical examinations.

The need of geomembranes in maintaining functional and environmental safety will only increase as artificial structure becomes further intricate and vast. In order to satisfy the demands of the coming generation of artificial systems, progressive HDPE Geomembrane liner manufacturers are formerly making investments in these trends.

Conclusion

It’s insolvable to overrate the significance of reliable and high- performing constraint systems in the dynamic world of artificial growth. HDPE geomembranes have shown themselves to be long- lasting, nicely priced, and ecologically friendly. They remain essential in numerous different operations, similar as resource conservation and Sheet operation.

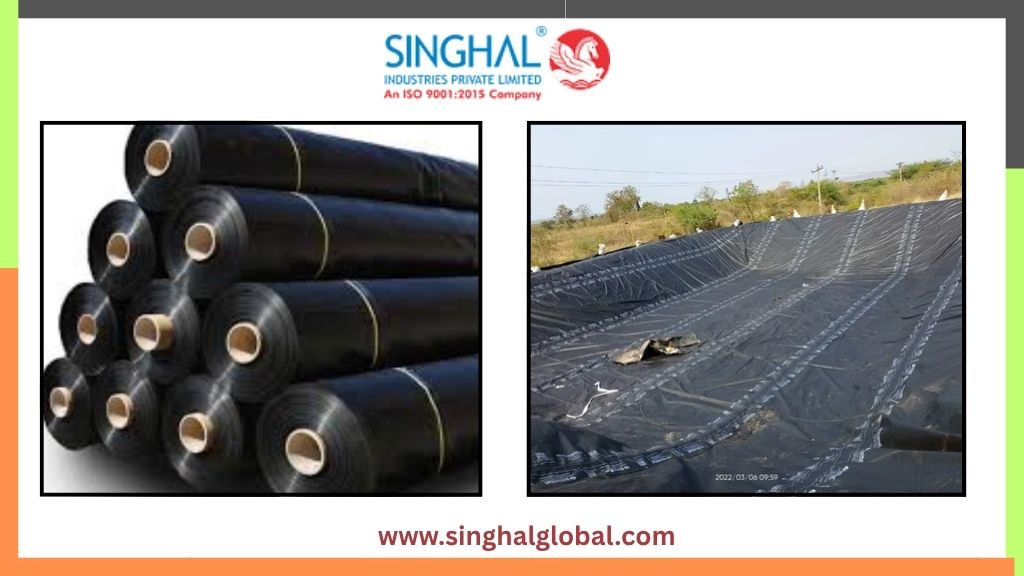

Singhal Industries Private Limited is one of the several suppliers in this request and has made a name for itself in the geomembrane product assiduity. Known for their fidelity to quality and invention, they give results that meet the requirements of the most demanding artificial settings while maintaining compliance and sustainability. opting a mate like Singhal Industries might be pivotal if you are planning a design that requires strong constraint.

FAQs

Q1. Who is the largest manufacturer of HDPE Geomembrane?

While there are several prominent players encyclopedically, Singhal Industries Private Limited is extensively honored as one of the leading HDPE Geomembrane manufacturers in India, offering transnational- grade quality and a wide range of product variants to suit different artificial requirements.

Q2. What’s the average HDPE Geomembrane price in India?

The HDPE Geomembrane price in India varies depending on consistency, quality norms, and customization. On average, it cadence, though bulk orders and specialized specifications can impact this significantly.

Q3. How do I choose the right HDPE Geomembrane liner manufacturer?

Choosing the right HDPE Geomembrane liner manufacturer involves checking for quality instruments, product range, client reviews, after- deals support, and the capability to meet design-specific conditions. Long- term trustability and specialized moxie should also be crucial deciding factors.