A great idea is only the beginning. Turning it into a reliable, working product takes planning, technical skill, and the right kind of support. That’s where professional electronics design services come in. These services, often offered by a full-service electronics design company, guide the journey from early concept to tested prototype.

Unfortunately, not all services are created equal. Knowing what to expect and what to demand can save time, reduce rework, and improve your end product.

Start With More Than a Schematic

Many projects start with a basic sketch or a block diagram. Some clients come in with a draft schematic. But even a well-drawn schematic is only a small part of the design journey.

Reliable electronics design services extend beyond simply listing parts on a page. They ask the right questions up front:

- What’s the end-use environment?

- Are there size or weight limits?

- What are the compliance or safety requirements?

This discovery phase shapes every design decision that follows. It’s also where hidden risks show up. That’s important because catching those early costs far less than fixing them later.

What a Strong Electronics Design Company Offers

An experienced electronics design company does more than assemble parts. It works as a partner, helping you balance performance, cost, and manufacturability.

Here’s what that includes:

- Component selection: Choosing parts based on cost, availability, and performance.

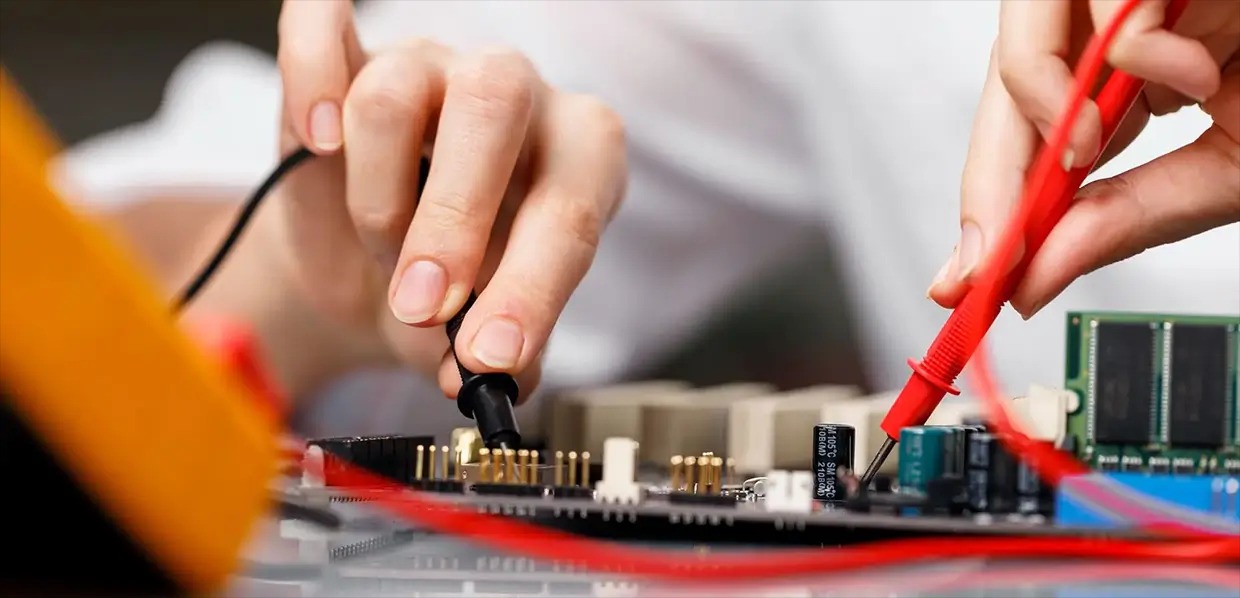

- PCB layout and routing: Designing a board that supports signal integrity, thermal control, and compact packaging.

- Power management: Making sure the product runs safely and efficiently.

- Design for Manufacturability (DFM): Creating designs that are easier and cheaper to build.

- Design for Test (DFT): Making the product easier to test at every stage.

- Regulatory planning: Preparing for certifications like FCC, CE, or UL.

Each step is an opportunity to spot issues before they grow.

Real-World Example: Environmental Sensor Design

A team developing an outdoor air quality sensor came to an electronics design company with a prototype that didn’t hold up in the field. Their board design overheated in direct sunlight and the battery drained too fast.

The design team made several key changes:

- Swapped out power-hungry components for lower-draw versions

- Redesigned the enclosure and PCB for better heat distribution

- Optimized firmware for energy use

The result? A sensor that performed better and lasted longer, without a complete redesign.

Communication Matters

Design can be fast or slow depending on how well teams communicate. A good design service uses shared tools and regular reviews. You should expect:

- Weekly check-ins: To track progress and flag concerns

- Version-controlled files: So everyone works from the same documents

- Clear documentation: So manufacturers know exactly what to build

These practices reduce errors and expedite the path to prototyping.

Prototyping and Testing

A reliable design service won’t just stop at a board file. They support prototype builds and help validate them. That means:

- Coordinating with assembly teams

- Providing test plans and procedures

- Iterating based on real-world test results

This hands-on support ensures that the prototype isn’t just functional; it’s also ready for refinement or production.

Avoiding Common Pitfalls

Too often, teams run into problems that better design services could have prevented:

- Missing test points: Makes board testing difficult

- Unspecified components: Delays sourcing

- No compliance strategy: Leads to failures in certification

A proactive design company helps you avoid these. They look ahead, not just at what the product does, but how it will be built, tested, and shipped.

What to Look for in a Design Partner

If you’re choosing a company to help with your next product, ask about:

- Their experience with similar products

- Their in-house capabilities (firmware, layout, prototyping)

- Their process for documenting and reviewing designs

Look for a team that can support you through every step, from design to delivery.

Key Takeaways

- Good electronics design services do more than draw schematics: they help guide the entire development process.

- A reliable electronics design company focuses on power management, manufacturability, testing, and regulatory planning.

- Clear communication and detailed documentation prevent costly delays.

- Prototyping support ensures you don’t stop short of a working product.

- Look for a team that works like a partner, not just a vendor.

The best design outcomes come from solid collaboration and thorough planning. Choosing the right partner from the beginning makes everything that follows smoother and more successful.